While 3D printing offers great design flexibility before an

object is printed, it is very hard for end-users to customize a

3D-printed object to their specific needs after it is printed. We

propose HotFlex: a new approach allowing precisely located

parts of a 3D object to transition on demand from a solid into

a deformable state and back. This approach enables intuitive

hands-on remodeling, personalization, and customization of

a 3D object after it is printed. We introduce the approach

and present an implementation based on computer-controlled

printed heating elements that are embedded within the 3D object.

We present a set of functional patterns that act as building

blocks and enable various forms of hands-on customization.

Furthermore, we demonstrate how to integrate sensing

of user input and visual output. A series of technical experiments

and various application examples demonstrate the practical feasibility of the approach.

My task involved creating proof-of-concepts and designing experiments for every primitive, pattern, and application described in our paper.

Figure 1. Application examples. a) An interactive shape-changeable bracelet. b) Interactive sealable treasure box with embedded TFEL display. c) Ergonomically customizable mouse: cutaway rendering and prototype after customization (cover removed to reveal deformation).

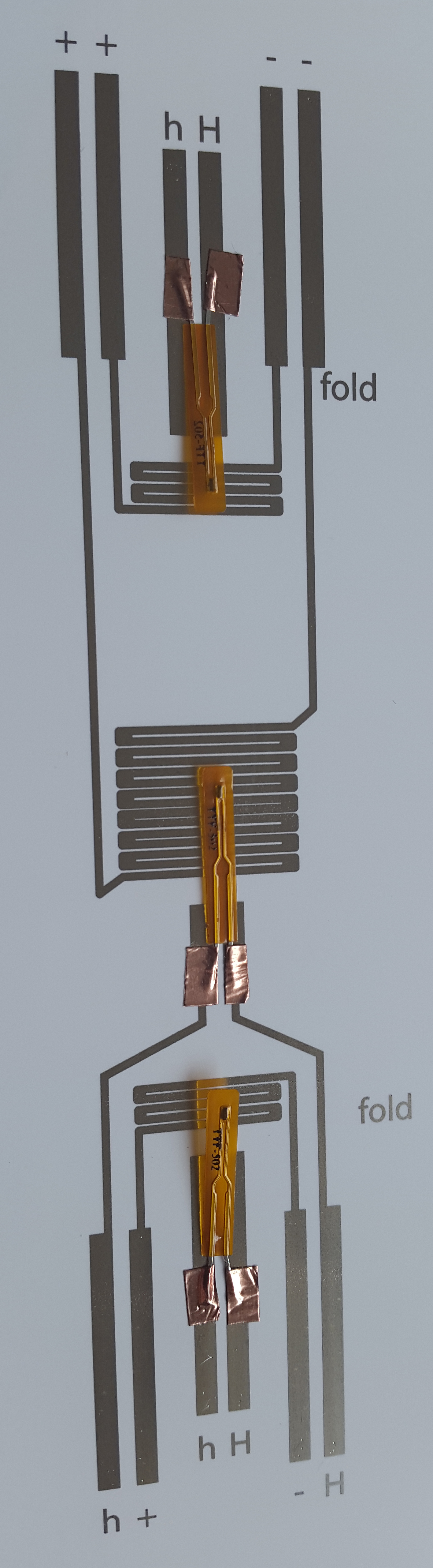

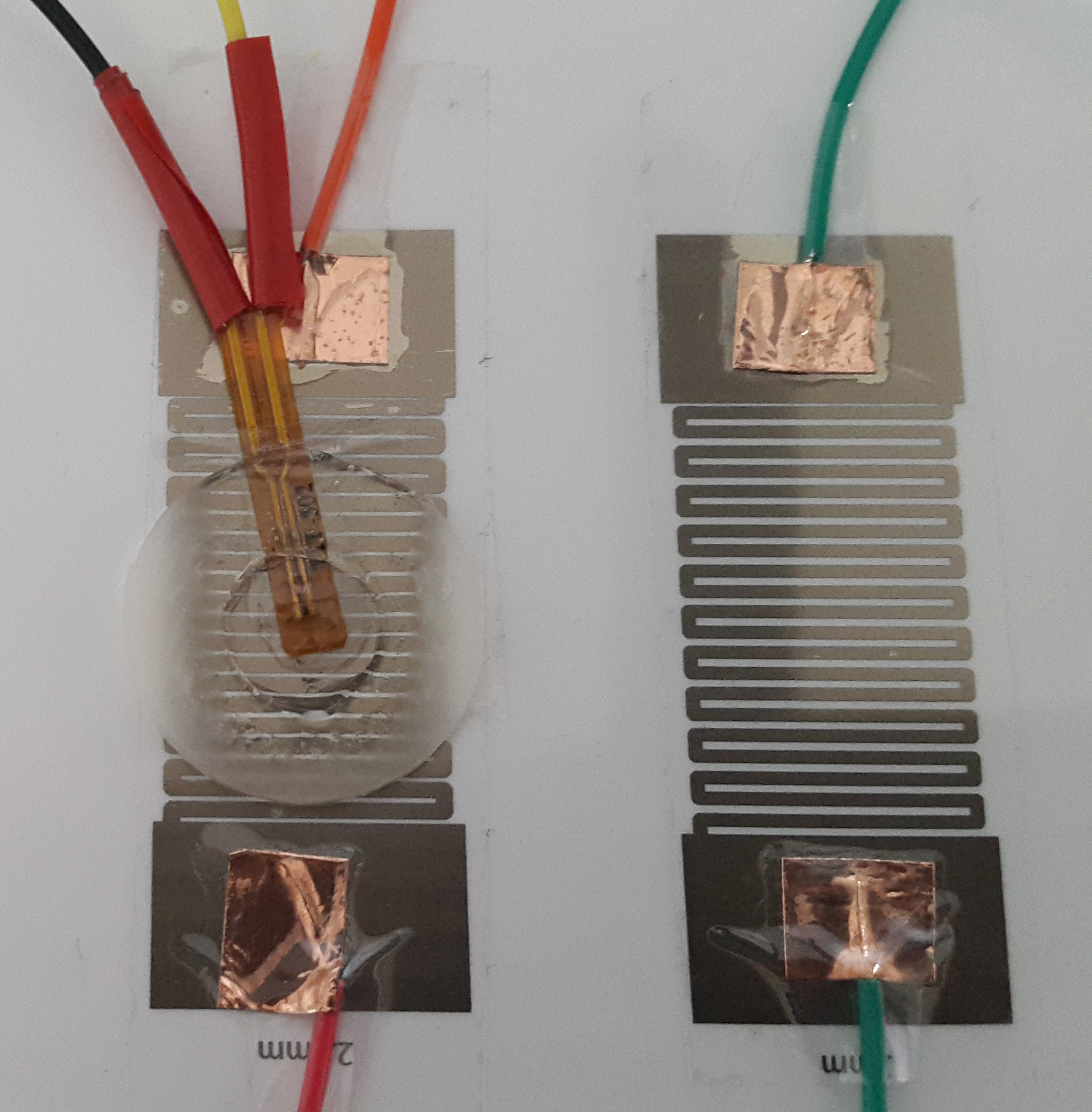

Figure 2. Inkjet-printed heating strip.

Figure 3. Inkjet-printed heating strip temperature test.

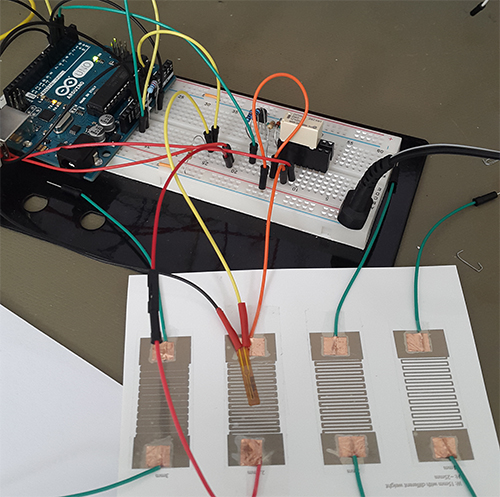

Figure 4. Hardware used to control heating strip.